SSP and GSSP Fertilizer Plants

CPG provides turnkey solutions for producing Single Super Phosphate Fertilizers. We have been catering to fertilizer industry from more than 30 years

Depending upon the requirement of the client, we deliver Single Super Phosphate(SSP) Fertilizer Plant and Granulated SSP Fertilizer Plant projects for both powder SSP production and granulated SSP production.

SSP Fertilizer Plant

Single super Phosphate is the most important single nutrient Phosphatic fertilizer containing 16% P2O5 in water-soluble form and has traditionally been very popular in agriculture sector. Raw material for SSP is rock phosphate and sulphuric acid, where rock phosphate is a natural deposit of calcium phosphate containing fluorine and carbonate.

OUR CLIENTS

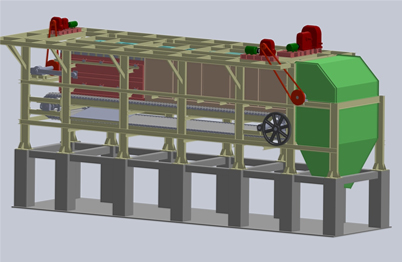

Our Solution for SSP Plants:

We provide a complete solution from handling of rock phosphate to packing of SSP powder. In this, we provide all mechanical, electrical and automation systems as a one-stop shop for customer.

- Ball Mill

- Separators

- Paddle Mixer

- Den

- Scrubbing system

- Granulator Rotary Drum

- HAG furnace

- Rotary Dryer

- Rotary Cooler

- Ball Mill

- Separators

- Paddle Mixer

- Den

- Scrubbing system

- Granulator Rotary Drum

- HAG furnace

- Rotary Dryer

- Rotary Cooler

Product Details :

Manufacturing Process

The manufacturing process of single super phosphate is explained briefly via flowchart shown below

Rock Phosphate Crushing & Storing

Rock Phosphate grinding to obtain required fineness

Dilution of Concentrated sulphuric acid

Basic mixing of rock phosphate and diluted sulphuric acid in MIXER

Cutting of large lump in DEN by DEN Cutter

Scrubbing of Gases through counter current water spray

Reaction of sulphuric acid and rock phosphate mixture obtained from Mixer in DEN

If requirement is of GSSP plant, then cured SSP is taken further to granulation circuit consisting of following sections

- Crushing of Cured SSP

- Granulation in Granulator Drum

- Drying Section

- Cooling Section

- Packing Section