Contract Manufacturing

CPG has been dealing in contract manufacturing and outsource manufacturing of plants for the last 60 years. We have been catering to many multinational companies such as SMS Siemag, Loesche, KHD Humbolt, Voest Alpine, Valmet, ENMAS Andritz, INTECO (Austria), Gebr Pfeiffer, Mecamidi HPP and many more. For us, quality and customer satisfaction have been two key motives for many decades. Further, to provide world-class products, we strictly adhere to DIN standards and in our manufacturing cycle, we even offer third party inspectional by international agencies such as Lloyds, TUV and a few more.

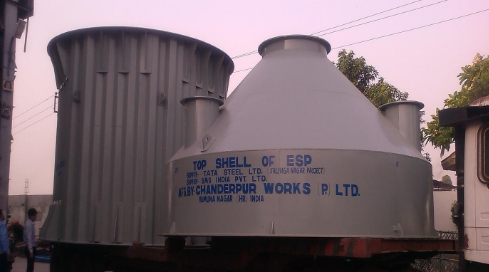

Some of recent contract manufacturing projects:

CPG’s Facilities

- In-house extensive machining and fabrication facilities. For more info, click here.

- Experienced in handling 130 tonnes single piece equipment

- In-house fully equipped quality assurance and inspection team. For our detailed quality assurance practice.

- All types of welding (SAW, MIG, MAG, FCAW, SMAW, TIG), qualified welders (for all positions & more than 20 years experience, approved from Llyods)

- Latest CNC Machines - VTLs, Borers, Plano Millers, VMC, Drilling.

- Advanced Machines - Robotic Welding, Coordinate Measuring Machine,3D Printing.

- Other Machines - Gear HOBBINGS, Facing Lathes, Plate Rolling Machines (upto 120 mm)

- Facility for delivering single piece equipment up to 150 Tons.

- Having ISO 45001:2018, ISO 9001:2015 Certification

- ASME “U” and “R” Stamp Certified Manufacturing Facilities

Gallery

CPG can cater projects to companies under contract manufacturing in five different ways:

- Manufacturing as per customer detailed manufacturing drawings

- As per customer’s general arrangement drawing, we can make manufacturing drawing using our design facilities and then manufacture using our manufacturing drawings

- From concept (lap scale and pilot scale) and customer experience, engineering for new equipment can be done. Through this, prototype can be generated.

- Import substitutions

We also undertake work of import substitution by designing the equipment for balance of plant that are not available during import. Under this method, one of our recent clients is India Gypsum Ltd. - Process Re-engineering

In this, we check existing plants and machines: performs energy audits, measures bottlenecks, quality audits and measures productivity of machines. After analyzing the performances of machines and process, we guide customer for process improvement with lowest investment either though installing energy efficient equipment or if needed altering the process. This service has been provided to many clients: Hindustan Lever, India Carbon and many more.