Rotary Kiln Cement Plant

CPG has an experience of successfully executing numerous complete Rotary Kiln Cement Green Field Projects, Cement Rotary Kiln Plant and Rotary Kiln Turnkey Cement Plant.

To make our solution easily understandable, we have split it into three sections:

- Raw Material Crushing, Grinding And Blending

- Pyro Processing

- Cement Production

Raw Material Crushing, Grinding and Blending

In this section, limestone is fed to a limestone crusher, where its size gets reduced. And then crushed limestone is stored in storage silos. The other materials Clay, Iron Ore and Bauxite are crushed if more than 20 mm and stored in respective storage yards. From the Storage yard, these materials are fed to the Raw Mill Hopper. The raw materials i.e. limestone, clay and other additives are then extracted in correct proportion by Electronic Weigh feeders and fed to Ball Mill for grinding to a fineness of 90 microns with the help of our grinding solution. After grinding, raw meal is stored in a storage silo.

- Know More :

- Ball Mill

- Classifier

- Rotary Dryer

- Grinding Solutions

Pyro Processing

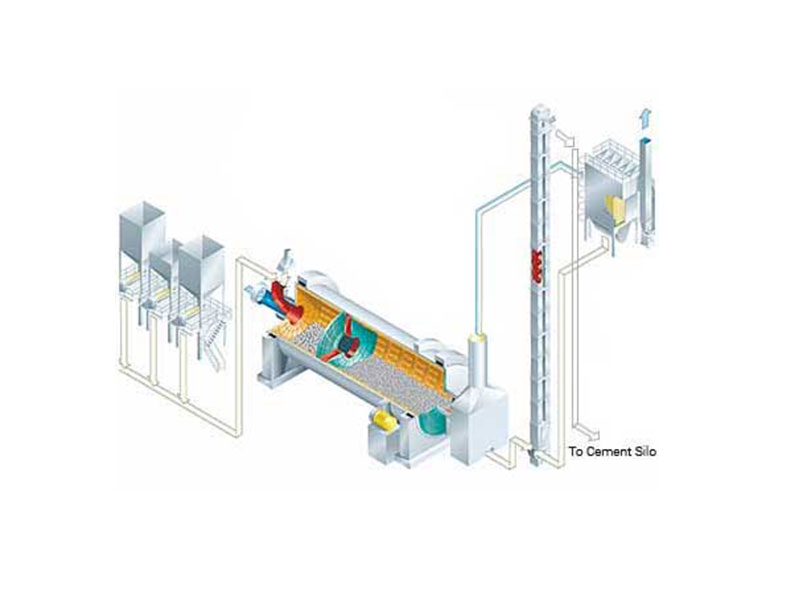

clinker grinding

The clinker from the clinker silo is mixed with 4-5% gypsum and then with the help of conveying system, it is fed to a cement mill for grinding to powder. This powder is called Ordinary Portland Cement (OPC). Additives like Pozzolana, Fly-ash and Slag are added in different ratios as per product requirements and Government Norms to produce PPC or PSC. The cement is stored in silos and packed in bags with the help of a packing machine. From the packing section, cement bags get loaded on to truck through the truck loading system.

- Know More :

- Ball Mill

- Classifier

- Rotary Dryer

- Grinding Solutions

We Provide Solutions

From Concept to Commissioning

- Layout

- Civil Designs

- Electrical & Automation

- Procurement

- In-house Manufacturing

- Quality Inspection

- Supply

- Civil Construction

- Equipment Erection

- Commissioning

To provide a single contact solution for the client, CPG provides customized solutions with:

- Plant Automation Systems

- Crushing Equipment’s

- Pollution Control Systems

- Mechanized/Automated Storage Systems

- Conveying Equipments

- Packing Systems

- Automated Loading and Unloading Systems