Bulk Blending Fertilizer Projects

NPK Complex Fertilizers are solid fertilizers in the form of uniform Powder commonly referred to by a sequence of three numbers, the first of which represents the percent Nitrogen expressed as N, the second, and the percent Phosphorus expressed as available P2O5 and the third, the percent Potassium expressed as soluble K2O. The Fertilizer Bulk Blending Plant and Fertilizer Blending Plant are very convenient to use because they contain all the three primary plant nutrients in the desired proportions.

ADVANTAGE OF FERTILIZER BLENDING:

Fertilizer blending provides solution to farmers to have the correct ratio of nitrogen, phosphorous, potash, and micro nutrients. With increased use of soil analysis and scientific crop management, fertilizer blending is often the best solution to provide farmers exactly what their crops require. Blending also makes inventory simpler for fertilizer suppliers, as they can meet about any analysis requirement quickly and efficiently.

OUR FERTILIZER BLENDING SOLUTION

We here at CPG are continuously improving technology for bulk blending According to ongoing trends in agriculture, it is often necessary to add micro nutrients, coatings and other additives into a blend. We believe that equipment and process technologies must grow with agricultural techniques. Same motto is foremost in the equipment & systems we offer.

Product Details :

OUR CONSIDERATIONS

We offer a variety of styles and sizes of fertilizer bulk blending systems to best fit our clients requirements based on their:

- Blend complexity

- Tons per hour & per year requirements

- Space availability

- Labor strength & cost

- Level of automation

- Local climate

- Raw materials

FEATURES OF OUR TECHNOLOGY

- Customized batch sizing up to plant capacity

- Product flexibility

- Quality blending

- Size uniformity

- Highly precised & reliable automation

- Single system operation

- Intelligent MCCs

- Customized Reporting (Process parameters, production, power consumption etc.)

- Eco friendly / Non polluting

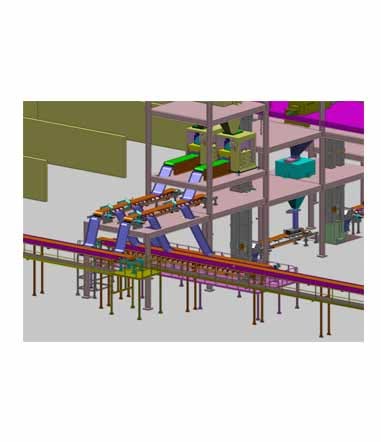

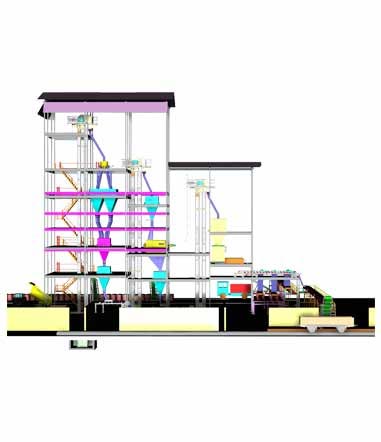

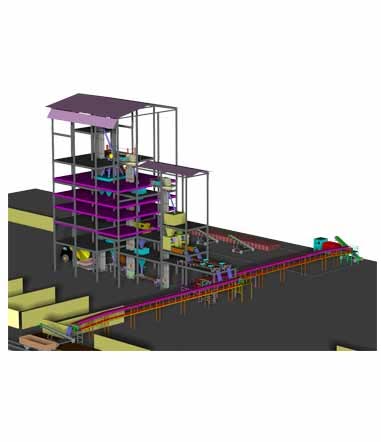

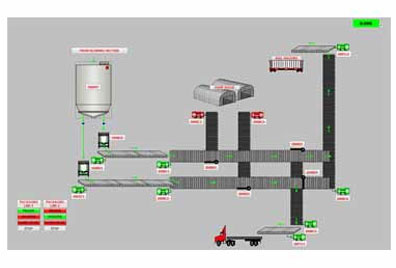

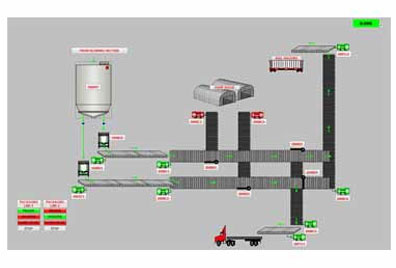

TYPICAL BULK BLENDING FERTILIZER PLANT

Manufacturing Process

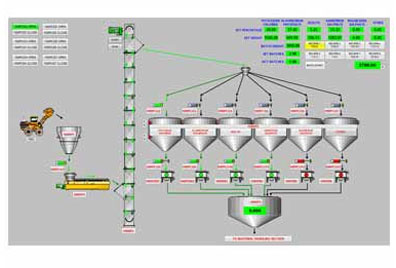

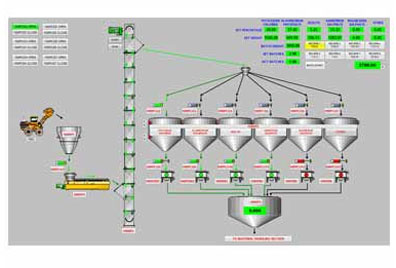

Raw Material Feeding and Batch Preparation Section

Starting from feeding of Cluster hopper, weigh feeder discharges the measured quantity of ingredients to bucket elevator which feeds the cluster hopper. Cluster hopper has separate compartments for each ingredient. Each compartment has a high and low level indicator governing the feeding necessity of the compartments. Individual Weigh batchers automatically weigh & discharge the selected ingredient in measured quantity as per the selected recipe to surge hopper. Surge hopper is having load cell to confirm whether the desired ingredient/batch quantity has been received or not. Providing accurate and reliable blending of dry soluble fertilizers.

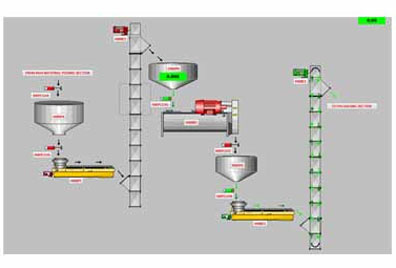

Blending Section

Material is then discharged to another hopper via automatic slide gate from where it is transferred to hopper before SSM via belt feeder & bucket elevator. Hopper before blender accumulates and weighs the ingredients of the batch prior to discharge into the mixer. Mixer is engineered for highly accurate and efficient mixing and coating of materials. Mixer is ideal for bulk blending with micro nutrients and adding liquid coatings & ultimate in speed, blend quality are. Shears are provided to DE lump while blending. SSM rapidly and thoroughly blends the fertilizer ingredients including liquid additives if there is any such constituent. The blended batch is discharged instantly in a dust-proof manner. Instant discharge protects blend quality.

Packing and Printing Section

From post blending hopper batch is transferred to packing hopper via belt feeder & bucket elevator. Automatic/semi-automatic bag filling & stitching machines packs the desired bag quantities. These bags are then transported to various locations by means of our material handling systems like truck loader, wagon loaders etc.

Some of key equipments of this plant

- Single shaft Mixer

- Bucket elevator

- Belt feeder

- Truck loader

- Packing Plant

- PLC System

- Instruments compatible with PLC