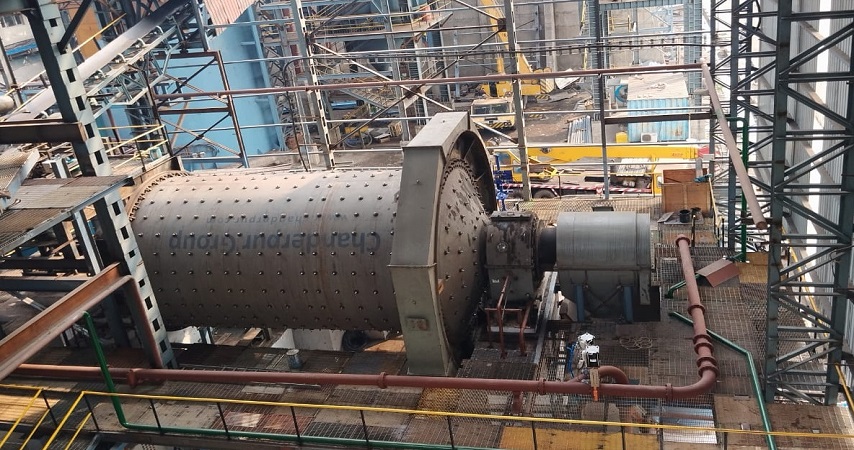

Rod Mill

CPG is a Supplier and manufacturer of Wet and Dry Type Rod Mills for the Grinding of Various Minerals.

Wet grinding rod mills are normally used in the mineral processing industry. Dry grinding is used in some areas; however, it is confronted with problems and should be avoided except where necessary.

Rod mills are very similar to ball mills, except they use long rods for grinding media. Rod mill is an efficient crushing machine for grinding various materials into powder which employs high carbon steel or special steel rods of nearly the same length as that of the drum, in place of steel balls in ball mills.

Types of Rod Mill

- Overflow

- End Peripheral Discharge

- Centre peripheral discharge

Successful Installation in Applications

- Chrome

- Iron ore

- Copper

- Slag

- Silica Sand

Salient Features

- To prevent the conditions leading to rod charge tangling, the length-to-diameter ratio is maintained at 1.4 to 1.6.

- Use less steel than a ball mill because of the lower speed and better contact between the media and ore.

- Less power is required since grinding rods are not cascaded and operate at lower peripheral speeds.

- Higher grinding efficiency is obtained since there is less void space in a rod charge compared to any other grinding media. This also results in lower steel consumption.

- Grinding rods can be kept in maximum working condition since worn rods may easily be withdrawn.