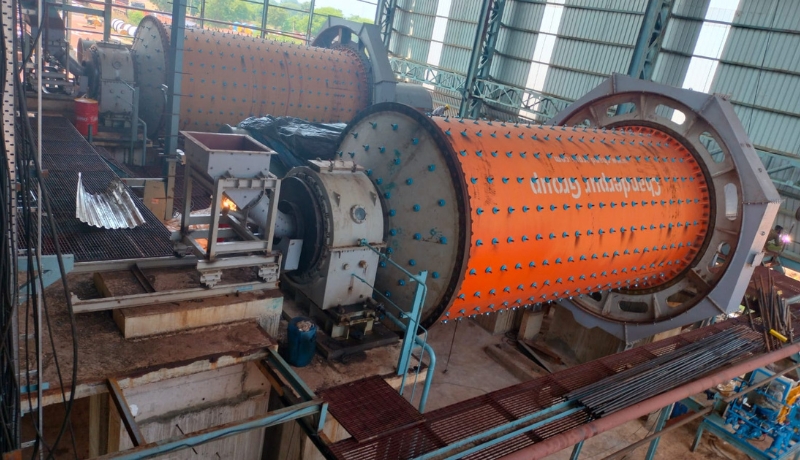

Ball Mill

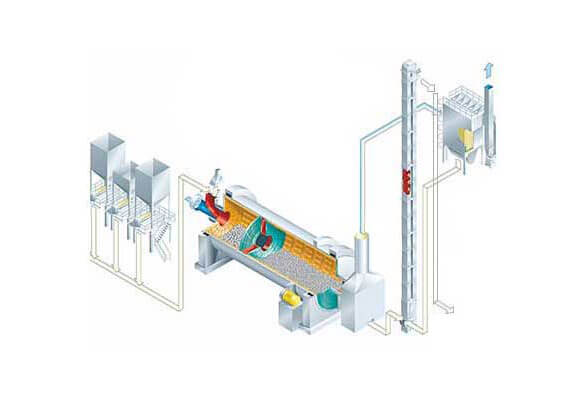

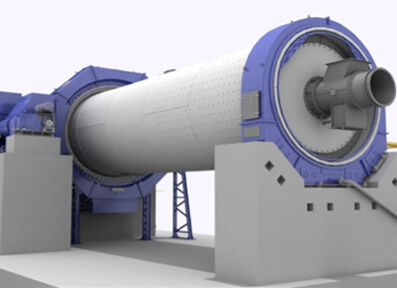

We bring forth a highly advanced Ball Mill, specifically engineered for both wet as well as dry cement grinding applications. Classified depending on the circuit design, bearing, grinding type and drive, the selection is made based on the product fineness, quality, and nature of raw material, site conditions and specific requirements. It is highly acknowledged for effective and quick grinding in several industries such as limestone, cement, coal, iron ore, chrome ore and many others. The major highlight of the mill is its fully automatic function with PLC control and instrumentation.

Highlights

- 450+ installations

- Robust & Reliable Design

- Easy Maintenance & Operation

- Manufacturing upto capability : Dia: 5.0 and Length: 19 mtr

- Fully automated system with PLC control & Instrumentation

- 100% spare availability in any part of world

Successful Installation in

- Grey & White Cement

- Limestone

- Coal

- Chrome Ore

- Iron Ore

- Silica Manganese

- Phosphate

- Slag

- Pet coke

- Alumina

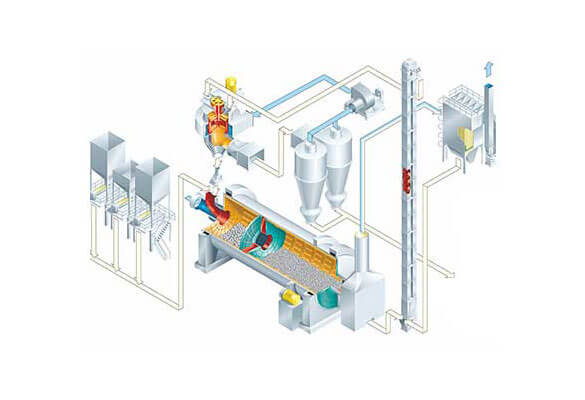

Selection of a Ball Mill

Selection of Ball Mill is done as per product quality, fineness, nature of raw material, site conditions and specific requirements like:-

- Open circuit or closed circuit

- Slide shoe bearing or Trunion Bearing

- Wet or Dry Grinding

- Central Drive or Girth Gear Pinion Drive

Technology

Widely recognized for its resilient designs, CPG comes with different designs for both wet as well as dry grinding.

CPG can offer two types of bearing design of Ball mill:

Highlights of Trunion Ball Mills

- White Metal Bearing

- Best known for easy operational benefits

- Designs of ball mills for all sizes of applications

- Self-Aligned Trunion bush bearing

- Close sealed bearing ensures better resistance to dust particles

- Oil housing with inspection door and proper sealing to avoid leakages

- Provided with pre-jacking oil lubrication system

- Manufactured using CNC profile machining crate

- White metal lining is ultrasonically tested before supply

Special features of our Shoe Slide Ball Mill

- In collaboration with Christian Pfeiffer Germany

- Tin based slide shoes with 81% of tin for

- Higher thermal connectivity

- Higher compression strength

- Higher fatigue and impact strength

- Higher corrosions resistance

- Built in Hydraulic jacks for easy maintenance and replacement

- No delicate large size mill head castings are necessary

- Large feed and discharge openings allowing the passage of considerable amounts of gas

Choose Your Drive

As per customer choice and requirement, CPG offers ball mills with three drive options :-

- 1. Girth Gear and Pinion Drive

- 2. Central Drive

- 3. Integral Drive

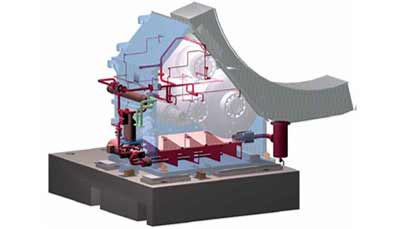

Central Drive Ball Mill

A classic and robust design meant for all site locations, user friendly, low maintenance, less capital cost, easy availability of spares.

- Easy to maintain

- No Grease Spray system required.

- The gearbox is flanged to the mill has no direct contact with the mill foundation, i.e. mill movements or any lowering of its foundation have no effect on the gearbox teeth

Integral Drive Ball Mill

Integral drive has two builtin, self aligning pinions in direct mesh with girth gear located on to a Flange on the mill shell. Mill is lubricated from an integrated oil lubrication system with circulation pump, oil filter and cooler, thus avoiding external girth gear lubrication cost, less space requirement and minor advantage in power consumption.