Lime Processing Plants

We offer turnkey solutions for lime plants including plant engineering, equipment supply, installation and commissioning. We have been serving this industry for the last six decades and have provided types of equipment worldwide.

Among lime plants technology, we cater for Hydrated Lime Plants, Quick Lime Plants and Precipitated Calcium Carbonate Plants. We offer lime plants including lime processing plants and lime processing machinery that incorporate the latest technology ensuring efficient functioning & optimum output. We are also one of the prominent lime plant manufacturers and lime kiln manufacturers in India.

We have a strategic collaboration with "QualiCal International" to supply highly efficient PFR kilns with capacities of up to 800 TPD and advanced Quick Lime Hydration Plants ranging from 5 to 30 TPH (excluding India). This partnership enables us to offer cutting-edge lime processing solutions that ensure optimized production and enhanced operational reliability for industries worldwide.

OPTIONS AS FINISHED PRODUCT

After calcination, lime can be obtained in following options

- Quick Lime

- Hydrated Lime

- Precipitated Calcium Carbonate

CPG provides technology for all the above options. We deliver projects on a turnkey basis from the crushing of limestone and up to packing plants. Our projects are fully automated and are controlled though PLC.

APPLICATIONS

- Cement Manufacturing

- Steel Plants

- Pulp and Paper Plants

- Glass Industry

- Water Softeners

- Paints

- Soil Stabilization

- Plastics

- Biodiesel Production

- Chemical Industry

- Petroleum

- Cleaners

Grounded Calcination Carbonate Plant

CPG provides solutions for Grinding Lime stone to fine & ultra-fine grinded size. As a turnkey solution, we supply primary crushers, screening systems, primary & secondary crushers and other conveying/loading systems. We have supplied more than 200 ball mills to date and are known around the globe for our ball mills.

.jpg)

- To know more about Grinding Solutions :

- Ball Mill

- Classifier

- Rotary Dryer

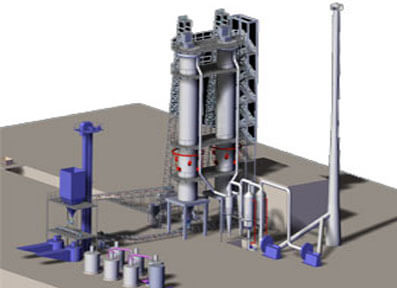

Quick Lime Calcination Plant

In calcination process, lime is cooked/calcined at 800°c in a kiln. We provide shaft kilns and rotary kilns for calcining limestone/lime sludge with multi-fuel options. Before calcination, exhaust gases of the kiln preheat lime. After coming out of the calcination area, quicklime is cooled by direct contact with cooling air.

Selection of Calcination Process

Limestone calcination process is selected based on limestone. If the size of the limestone is less than 4 inches and the capacity of the plant is less than 200 tonnes per day, then a shaft kiln is selected. Whereas for higher capacities and small stone-size sludges (industrial waste), a rotary kiln is installed.

Fuel options

Kiln can be oil-fired/gas fired or pulverized coal can be used as fuel. Even the gas-fired kilns can be fuelled through biomass by using our biomass gasification system. To know more about gasification system.

Lime Calcination Solution For Quick Lime

In calcination process, lime is cooked/calcined at 800°c in a kiln.We provide shaft kilns and rotary kilns for calcining limestone/lime sludge with multi-fuel options. Before calcination, exhaust gases of the kiln preheat the lime. After coming out of the calcination area, quicklime is cooled by direct contact with cooling air.