Classifier

The working of Classifier is based on the natural laws of centrifugal, gravitational and flow forces that bring about the classification in elements of different sizes. It has excellent ability to handle various types of materials including quartz sand, gypsum, lime, cement, iron ore, coal and other raw materials. Acknowledged in the global market place for its wear free confined air seal, smooth drive and unbreakable strong lining, this equipment provides maximum economy even during maintenance.

Air Classifier Technology by Christian Pfeiffer, Germany

Highlights

- Top cut from 10 µm and higher

- Air flow and speed of the rotating cage adjustable corresponding to your finish product

- Constant separating conditions in the whole separating zone

- Bearing cartridge and drive are accessible from the top (easy maintenance)

- Nearly wear free air confined sealing for the rotating cage

- Easy maintenance, comfortable large maintenance flaps

Successful Installation in

Our high efficiency air classifiers are an assurance for the quality of materials such as:

- Cement

- Gypsum

- Raw meal

- Lime

- Coal / Petcoke

- Iron ore

- Quartz sand

- Feildspar

- Graphite / Fly ash

- Wollastonite

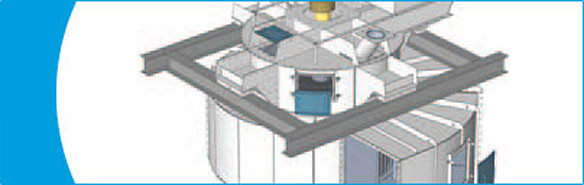

The Clever Concept

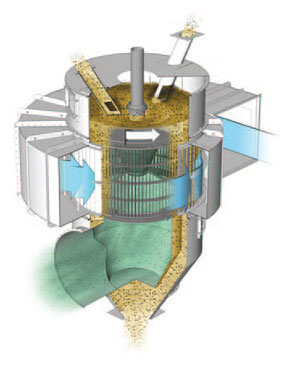

Our high efficiency industrial air classifier for cement are designed in such a way that the material-tobe- classified arrives at the distribution plate by two diametrically arranged feeding chutes. Due to the high speed of rotation, the material is then pushed to the side walls. In this process, any possible agglomerates disintegrate before the dissolved material falls into the classifying area below. In falling, the material is caught by a horizontal airflow which carries the smaller particles through the rotor blades into the rotating cage. From there, they are either carried to cyclones or are classified as fine material through a filter system. During this classi fying process, heavy particles are not caught by the air flow but fall into the coarse material cone.

The classifier’s focus:

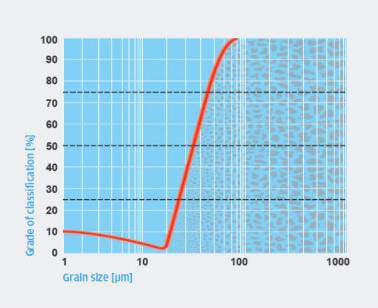

its classification effect

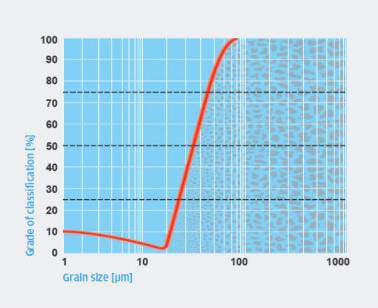

An air classifier divides material flow into two parts. One of them consists of fine material, the other one of coarser parts. Centrifugal, gravitational and flow forces impact on mass elements which are of di"erent sizes and use natural laws to bring about classification. The “tromp curve“ illustrates how e!ciently the materials are classified: The lower the deviation from the vertical, the more precise the sharpness of classification. The lower the deviation from the horizontal line, the greater the classification effect.

Features

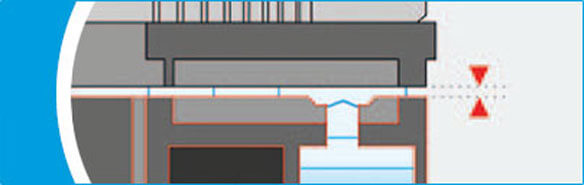

Confined Air Seal:

Wear-free thanks to Air Cushion.

The confined air seal does not wear out. This is due to a special construction: the adjusting ring and the rotating cage do not touch each other, they are separated by a small gap. Air is pressed into this gap making it work like a cushion and providing smooth operation. When escaping between the sealing rings, the air prevents dust and coarse-grained material particles (oversized particles) from entering.

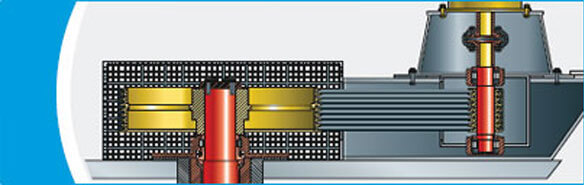

Maximum Economy:

Even During Maintenance.

The bearing cartridge in our high efficiency air classifiers is installed outside the dust-loaded zone of the rotating cage. During maintenance it is removed in full, with the rotating cage remaining in the classifier. All of the classifier‘s components can also easily be reached through ample-sized inspection doors.

Smooth Drive:

Reliable and Long-lasting.

Our high efficiency air classifiers are smoothly driven by V-belts. Depending on motor capacity, the belt pulley starts moving either directly or with a reducer unit.

Strong Lining:

An Unbreakable Protection.

A chemically bound cemented ceramic protects the distribution plate, the lateral parts of the dispersion zone, the fi nes discharge tube as well as the casing parts beneath the classifying zone.